Automotive

Polishing/polishing, buffing, buffing, and satin finishing of automotive-related objects: rims/wheels, profiles, handles, knobs, luggage racks, exhaust pipes. Materials: zamak, aluminum, stainless steel.

Buffing

Designing automatic machines for buffing and satin finishing metals and other surfaces. We have the longest expertise in this process and one of our key knowledge.

-

See all

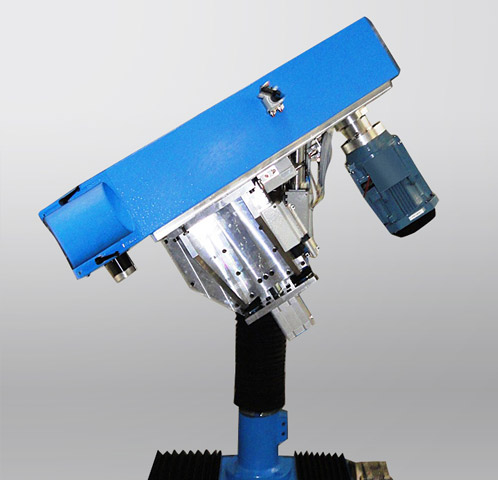

See allC.N.C. buffing unit

A technological evolution that combines the advantages of the Rotary Index Table with the innovative and flexible multi-axis CNC buffing units.

This new solution’s goal is to reach and buff the piece’s surfaces that a common buffing unit cannot do. The completeness and the great number of operations that may be performed by this kind of unit make are similar to a robot’s movement capability. -

See all

See allContinuous rotation table with C.P.L. type buffing unit

This type of machine is to consider the first level of automation of the buffing process thanks to the Rotary Table.

Operating units to set around the Rotary Table are essential to complete each step of the buffing process and, depending on the product nature and the cycle time duration, possess different characteristics.

The characteristics that distinguish these machines are reliability, usage easiness and processing speed. -

See all

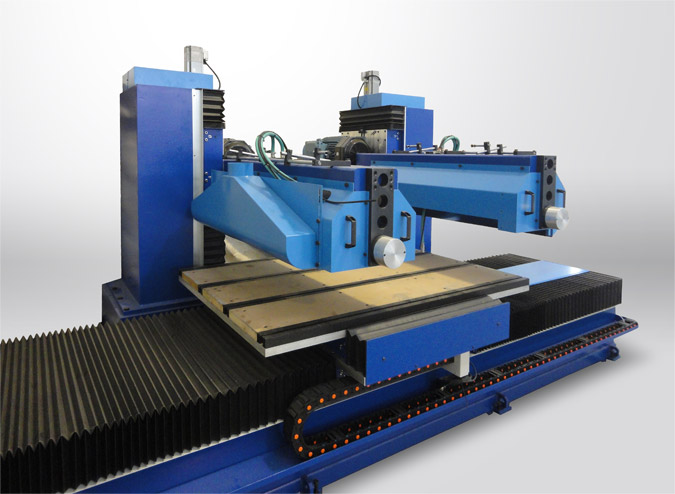

See allMobile/static flatbed with polishing unit (BM)

The mobile bench or static bench solutions can be associated with any buffing unit, from the basic ones needed to operate on a linear surface to the most complex CNC ones.

The necessity to find a way to perform the loading/unloading task within hidden times, meaning during the simultaneous processing of the same number of pieces, is very important for these units, too.

Polishing

The various technological solutions offered by C.O.S.M.A.P. to automate polishing, deburring and satin finishing processes. We use our rotary table machines and robotic cells.

-

See all

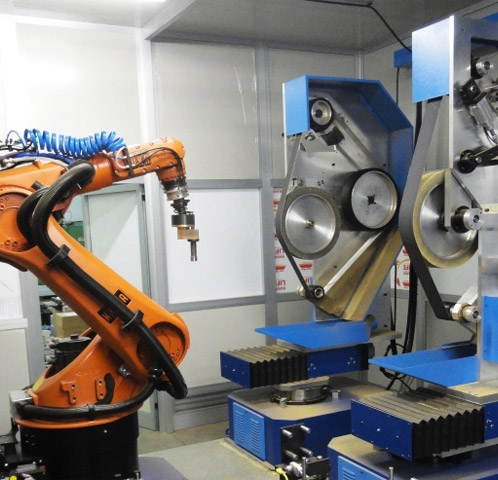

See allRobotic Cell (IR)

Robotized cells distinguish themselves thanks to their versatility in facing the polishing process.

Thanks to special polishing units it is possible to shift the tool needed in the process from, for example, simple polishing disks to flap wheels, rather than a scotch-brite buff. -

See all

See allIndexed rotary table with C.S.L. type polishing/buffing unit

This type of machine is to consider as the first level of automation of the polishing process thanks to the Rotary Table.

Operating units to set around the Rotary Table are essential to complete each step of the polishing process and, depending on the product nature and the cycle time duration, possess different characteristics. -

See all

See allIndexed rotary table with C.N.C.S. type polishing/buffing unit

A technological evolution that combines the advantages of the Rotary Index Table with the innovative and the flexibility of the multi-axis CNCS polishing units. This solution allows improving the polishing process using the Rotary Index Table, with the advantage of being able to perform it with hidden cycle times. This new solution’s goal is to reach and polish some surfaces that a common unit may find difficult to get to. The completeness and the great number of operations that may be performed by this kind of unit make it very likely to recall a robot’s movement capability.

Combined

C.O.S.M.A.P.’s most distinctive feature throughout the years, along with great reliability, is the possibility to combine our buffing and polishing processes. It is one of our expert and innovating solutions.

-

See all

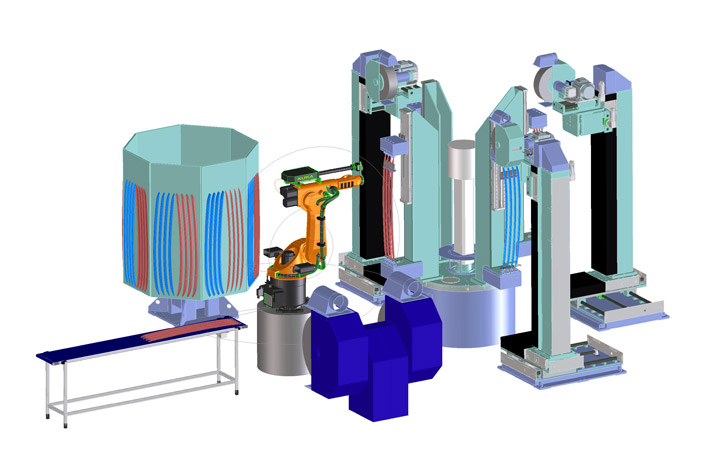

See allRobotic Cell and Rotary Table

A continuously spreading solution reassuming the concept of Lean Manufacturing and processing efficiency, plus the robot-equipped with a polishing cell and the rotary table for buffing.

Two dramatically different concepts bound by one characteristic: the cycle time management.

This solution is based on the idea of hiding any processing step within the same cycle time.