-

TR + CNCSIndexed rotary table with C.N.C.S. type polishing/buffing unit

TR + CNCSIndexed rotary table with C.N.C.S. type polishing/buffing unit

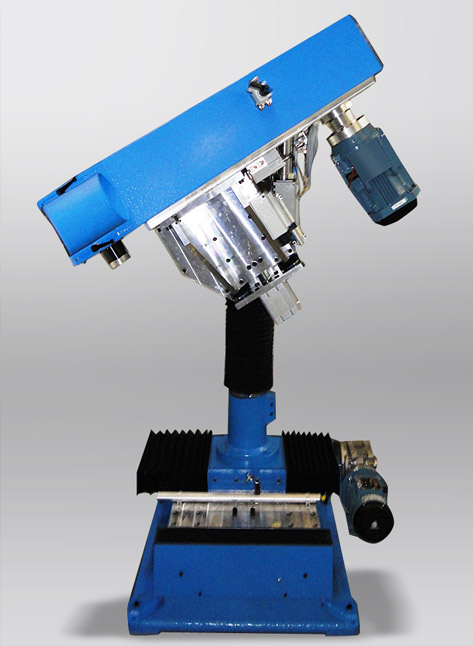

TR + CNCS

Indexed rotary table with C.N.C.S. type polishing/buffing unit

A technological evolution that combines the advantages of the Rotary Index Table with the innovative and the flexibility of the multi-axis CNCS polishing units. This solution allows improving the polishing process using the Rotary Index Table, with the advantage of being able to perform it with hidden cycle times. This new solution’s goal is to reach and polish some surfaces that a common unit may find difficult to get to. The completeness and the great number of operations that may be performed by this kind of unit make it very likely to recall a robot’s movement capability.

The piece-holding spindle unit may integrate rotation movements and turning movements that may be interpolated with buffing movements.

Each buffing unit’s movements are performed thanks to five controlled axes with an additional pneumatic springing controlled by the contact wheel. Therefore, each station has seven controlled and interposed axes, considering the two on the table and the other five from the units.

Pros:

- High production rates thanks to the Rotary Table and hidden loading/unloading times.

- CNC buffing unit flexibility, allowing to buff any object, even complex-shaped ones.

- Quick and certified machine set-up, thus immediate production change.

- Programming easiness with self-learning system, with no need to learn any machine-programming language.

- CNC unit sizing variable according to the client’s needs (from CNC mini to heavy CNC).

Information request

Please fill the below form, and we will contact you as soon as possible.