-

PolishingAutomatic machines for polishing

PolishingAutomatic machines for polishing

The various technological solution offered by C.O.S.M.A.P. for the automatization of polishing, deburring and satin finishing processes are based on the employment of the rotary table and its great efficiency when interfaced with our various models of working unit, or when integrated into a robotic cell.

Employing these types of processing system, alone or coupled, will create a high-performing, flexible, and user-friendly machine.

Within this section, you will find our solutions sorted by type of application and distinctive customizable traits for each field of application in the most efficient, innovating, and competitive way.

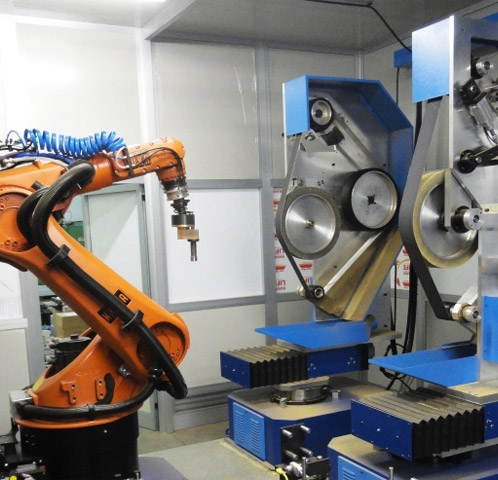

Robotic Cell

Robotic cells are the most flexible solutions to face delicate and complex polishing/linishing operations. The aim is to make them increasingly performing and productive.

Our robotic cells distinguish themselves thanks to their versatility in facing the polishing process.

Thanks to special polishing units, it is possible to shift the tool needed in the process from, for example, simple polishing disks to flap wheels, to scotch-brite buffs, etc.

Furthermore, each unit is equipped with a controlled axis that allows the rotation of the entire polishing head on a 0 to 180 degrees angle, with the intent to ease and speed up the polishing process, helping the robot as it needs to reach uneven surfaces or when its arm stands in the way.

Each unit is also mounted on a linear, controlled-axis with a ball screw to manage the operating pressure and to compensate the consumption of the buff, and/or to reposition the unit if required.

This way, the robot settings do not need any further modifications, as the robot is capable of moving back and forth easing and speeding up the product processing, hence improving the productivity of the machine and its versatility.

Each robotic cell can be designed and developed with a loading/unloading automatic system according to the nature of the specific product to process: double pallet, belt conveyor system, vertical/drum loader system, just to mention a few.

Our robotic cells may be single, double, or triple according to the client’s processing needs.

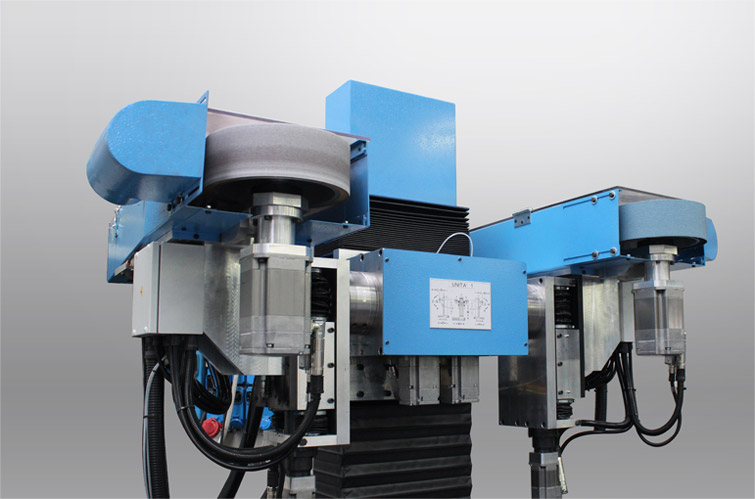

Indexed Rotary Tables

The starting point to automatize the buffing process with an indexed rotary table

This type of machine is to consider as the first level of automation of the polishing process thanks to the Rotary Table.

The operating units set around the Rotary Table are essential to complete each step of the polishing process and, depending on the product nature and the cycle time duration, possess different characteristics.

The characteristics that distinguish these machines are reliability, easiness of use and processing speed.

COSMAP, as a Rotary Table automatic metal polishing and buffing unit designer and builder, can respond to any request, granting the client the ideal quantity of perfect-sized units needed for the intended use.

These simple, yet highly effective polishing units can be equipped with multiple simple electric or servo-controlled axes, to increase the processing performance.

To speed up the change of production, these working units are pre-set for the auto-positioning – the auto-positioning is a function that allows the automatic working unit’s positioning thanks to motorized electric axes.